Introduction

Cross-docking stands as a revolutionary logistics strategy that enhances efficiency, reduces costs, and accelerates product movement. This method minimizes storage time by facilitating direct shipments from suppliers to customers without prolonged warehousing. Businesses adopting benefit from optimized supply chain processes, improved inventory management, and enhanced customer satisfaction. By eliminating unnecessary handling, companies streamline operations, reduce transit times, and enhance overall logistics performance. This innovative approach proves invaluable in industries requiring rapid fulfillment, such as retail, automotive, and perishable goods sectors. Understanding mechanisms provides insight into its advantages and challenges within the modern logistics landscape.

What is Cross-Docking?

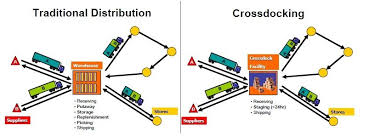

Cross-docking refers to a logistics practice where inbound shipments get sorted, consolidated, and transferred directly to outbound transportation. This process occurs with minimal storage, significantly reducing inventory holding costs and improving supply chain efficiency. Products arrive at a docking terminal, undergo sorting based on their destination, and move swiftly to outbound carriers. Companies implementing eliminate traditional warehousing needs, enabling faster product movement and reduced operational expenses. With precise coordination, businesses achieve seamless distribution and enhance responsiveness to customer demands. The strategic application of optimizes logistics efficiency and ensures goods reach their final destination without delays.

How Cross-Docking Works

It involves several coordinated steps that ensure smooth product transfer from suppliers to customers without prolonged storage periods. The process begins when inbound shipments arrive at a designated distribution center, where workers immediately unload and sort products. After categorization, items move directly to the outbound loading dock for immediate dispatch. Advanced technology, such as barcode scanning and real-time tracking, enhances accuracy and efficiency during product sorting. Companies implementing rely on meticulous planning, seamless communication, and advanced logistics software to ensure error-free execution. This well-structured approach allows businesses to maintain supply chain fluidity and prevent inventory stagnation.

Types of Cross-Docking

The comes in multiple forms, each designed to cater to different industry needs, supply chain structures, and operational goals. One common type is retail where products arrive pre-packaged for specific stores and are directly shipped to their destinations. Manufacturing cross-docking involves receiving raw materials or components and immediately transferring them to production lines without unnecessary storage. Distributor consolidates multiple shipments from various suppliers, organizing them for streamlined distribution to retail locations. Opportunistic cross-docking occurs when businesses capitalize on unplanned shipment opportunities to reduce transit times and optimize delivery efficiency. Understanding these cross-docking types helps businesses tailor logistics operations to specific industry requirements.

Benefits of Cross-Docking

Implementing cross-docking provides businesses with numerous advantages, enhancing efficiency, reducing costs, and improving customer satisfaction through streamlined logistics. By eliminating storage needs, companies significantly lower warehousing expenses and minimize inventory holding costs. Faster product movement reduces delivery lead times, ensuring customers receive their orders promptly. With reduced handling, businesses experience fewer product damages, improving overall quality assurance. Additionally, streamlined operations enhance supply chain agility, enabling companies to respond swiftly to demand fluctuations and market trends. Retailers, manufacturers, and distributors benefit from enhanced efficiency, making an essential strategy for optimizing modern supply chain management.

Challenges and Considerations in Cross-Docking

Despite its advantages, presents challenges that businesses must address to ensure successful implementation and operational efficiency. Effective coordination among suppliers, carriers, and distribution centers is crucial for seamless execution. Companies must invest in advanced logistics technology, such as real-time tracking and warehouse automation, to enhance accuracy and efficiency. Infrastructure readiness, including sufficient dock space and skilled personnel, plays a critical role in smooth operations. Additionally, requires strong supplier relationships to ensure timely and accurate shipments. Overcoming these challenges allows businesses to maximize the benefits of and achieve supply chain excellence.

Industries Benefiting from Cross-Docking

Various industries leverage to optimize supply chain efficiency, reduce costs, and accelerate product delivery to end customers. The retail industry benefits from rapid inventory turnover, ensuring shelves remain stocked with in-demand products. Automotive manufacturers use to expedite component deliveries, streamlining production processes and minimizing assembly line delays. Perishable goods sectors, including food and pharmaceuticals, rely on to maintain product freshness and meet strict regulatory requirements. E-commerce companies optimize order fulfillment by utilizing to reduce delivery times and enhance customer satisfaction. Each industry adapts strategies to improve operational efficiency and maintain a competitive edge.

Future of Cross-Docking in Supply Chain Management

As technology advances, continues evolving, integrating innovative solutions to enhance efficiency, accuracy, and scalability within supply chains. Artificial intelligence and machine learning enable predictive analytics, allowing businesses to optimize shipment planning and demand forecasting. Robotics and automation streamline product handling, reducing reliance on manual labor and minimizing errors in sorting and distribution. The Internet of Things (IoT) enhances real-time tracking, providing precise visibility into shipment movements and improving coordination. With increasing e-commerce demand and supply chain digitization, cross-docking remains a critical logistics strategy, driving efficiency and responsiveness in modern distribution networks.

Conclusion

The revolutionizes logistics by minimizing storage time, reducing costs, and enhancing supply chain efficiency across multiple industries. Businesses embracing this strategy experience improved inventory management, faster delivery times, and enhanced customer satisfaction. While implementation challenges exist, companies investing in advanced technology and strategic planning can overcome obstacles and maximize cross-docking benefits. As supply chain demands evolve, cross-docking remains a vital logistics approach, ensuring seamless product movement and maintaining competitive advantage. By understanding and leveraging cross-docking’s potential, businesses optimize operations, drive efficiency, and achieve long-term success in an increasingly dynamic market.

FAQs

1. What makes cross-docking different from traditional warehousing?

The eliminates prolonged storage by transferring products directly from inbound shipments to outbound transportation without intermediate warehousing.

2. Which industries benefit most from cross-docking?

Retail, automotive, perishable goods, and e-commerce industries benefit significantly from cross-docking due to its speed and efficiency advantages.

3. What technology supports cross-docking operations?

Barcode scanning, real-time tracking, warehouse automation, and artificial intelligence enhance accuracy, coordination, and efficiency in operations.

4. What are the main challenges of implementing cross-docking?

Challenges include supplier coordination, infrastructure readiness, skilled labor availability, and investment in advanced logistics technology for seamless execution.

5. How does cross-docking impact customer satisfaction?

By reducing delivery times, minimizing product handling, and ensuring faster order fulfillment, enhances overall customer satisfaction and supply chain efficiency.